Environmental remediation is the removal of contaminants and pollutants from environmental media such as soil, sediment, groundwater, or surface water for the general protection of human health and the environment. Remediation is usually subject to regulatory requirements, and also can be based on assessments of human health and ecological risks.

Ranger has completed numerous remediation projects in the southwest region of the United States, using various forms of remediation to aide in the cleanup of contaminants released into the environment. Ranger excels in the following areas of environmental remediation:

What is Bioremediation?

Bioremediation is any process that uses microorganisms, fungi, green plants, or their enzymes to return the natural environment altered by contaminants to its original condition.

What can Ranger do for you?

With our in-house geologists, biologists, and environmental scientists, Ranger can design and implement a site specific bioremediation system that will help remediate and clean the groundwater and soils at contaminated properties. Bioremediation is a safe, clean, and effective way to remediate a contaminated property because it facilitates a natural degradation of pollutants without interruption of site activities with in-place remediation equipment.

What is a Remediation system?

What is a Remediation system?

A remediation system is equipment that aides in the cleanup process of sites where contamination has affected both underground soils and groundwater. Remediation systems are operated 24 hours a day, 365 days a year.

What can Ranger do for you?

What can Ranger do for you?

Ranger can install and operate a variety of the equipment needed to remove or treat pollutants in the subsurface soils and groundwater. Ranger personnel can engineer the system needed and obtain the necessary permits from City, State, and Federal governments to achieve your clean-up goals. Ranger personnel can install and operate various types of equipment and systems related to the following:

- Thermal/catalytic oxidizers (electric or gas powered)

- Internal combustion engines

- Soil vapor extractions units

- Groundwater pump and treat

- Bioremediation

- Air Sparging

Or ANY combination of those mentioned and more!

What is Mobile Dual Phase Extraction?

What is Mobile Dual Phase Extraction?

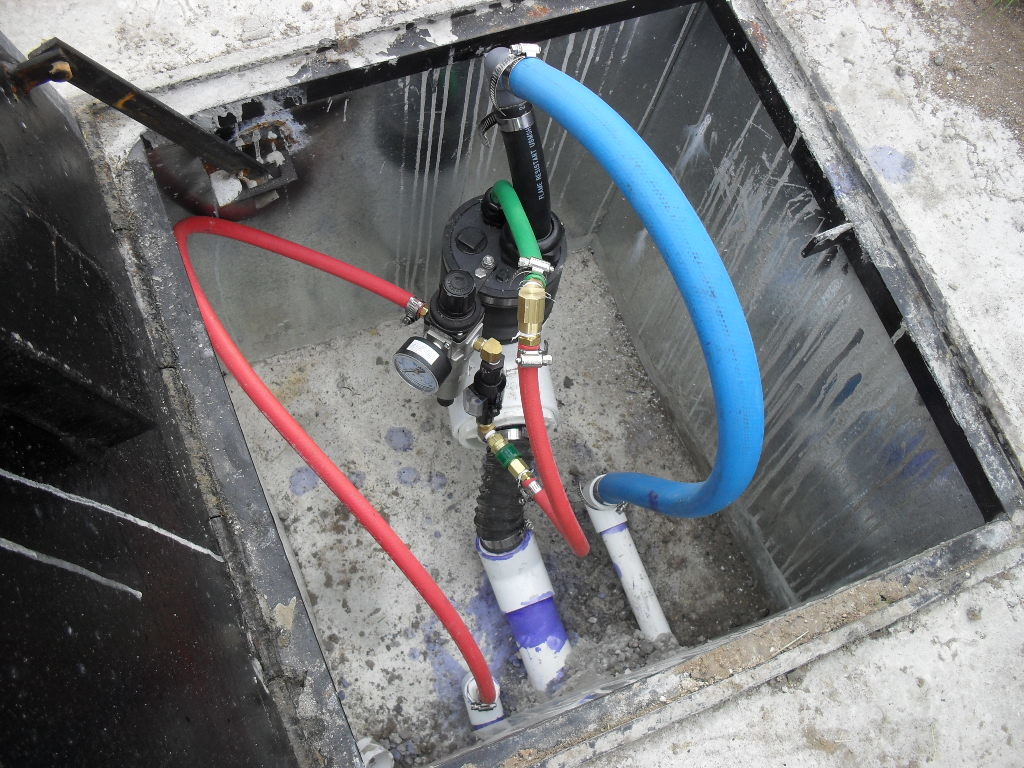

Mobile Dual Phase Extraction (MDPE) is a type of remediation technology used in the removal of Phase Separated Hydrocarbon (PSH) and Volatile Organic Compounds (VOC’s) contamination from the subsurface of sites impacted by underground releases. “Dual Phase” means that remediation of two separate subsurface constituents are going on simultaneously; liquid and vapor. MDPE is an effective form of remediation because these extraction units are mobile and can be moved to a variety of locations around a site to achieve maximum contaminant removal.

What can Ranger do for you?

Ranger has two MDPE units that are effective at remediating contamination from any site. Ranger currently performs the vast majority of our MDPE events in the state of Texas; however, because our units are mobile we can mobilize to any location quickly and effectively.

MDPE can be used and is effective in virtually all geologic units. Below is a general outline of the remediation process.

MDPE can be used and is effective in virtually all geologic units. Below is a general outline of the remediation process.

- Pneumatic pumps remove contaminated groundwater

- Vacuum pumps remove contaminated vapor trapped in the soil/subsurface

- The contaminated vapor is treated on-site

- The contaminated groundwater is either stored or treated on-site

What is Non-Aqueous Phase Liquid?

What is Non-Aqueous Phase Liquid?

Non-Aqueous Phase Liquid (NAPL) is any form of contamination that is not soluble in water. There are two forms of NAPL, dense and light. Light NAPL (LNAPL) has a lower density than water while dense NAPL (DNAPL) has a higher density than water. Examples of LNAPL are gasoline and other petroleum hydrocarbons, and examples of DNAPL are chlorinated solvents that are commonly used at dry cleaning facilities.

What can Ranger do for you?

Ranger specializes in a variety of NAPL removal techniques which are geared toward the type of contamination and other site variables. Ranger has the ability to fingerprint the type of contamination and NAPL at your site and design the remediation technology to maximize the effectiveness of the cleanup activities.

Ranger specializes in a variety of NAPL removal techniques which are geared toward the type of contamination and other site variables. Ranger has the ability to fingerprint the type of contamination and NAPL at your site and design the remediation technology to maximize the effectiveness of the cleanup activities.

What is Air Sparging?

What is Air Sparging?

Air sparging is a remedial technology that reduces concentrations of volatile organic compounds in petroleum products that are adsorbed to soils and dissolved in groundwater. This technology involves the injection of clean air into the subsurface enabling a phase transfer of hydrocarbons from a dissolved state to a vapor phase.

What Ranger can do for you

Ranger can design and implement injection wells that are site specific to the geology of a site for efficient and clean remediation of subsurface contamination. Typically, when you implement air sparging to a property, a soil vapor extraction system is combined within the remedial design to remove and treat the vapor contamination.

Ranger can design and implement injection wells that are site specific to the geology of a site for efficient and clean remediation of subsurface contamination. Typically, when you implement air sparging to a property, a soil vapor extraction system is combined within the remedial design to remove and treat the vapor contamination.

What is Waste Characterization and Disposal?

Characterization of wastes is necessary to properly classify the wastes and determine disposal options. The waste characterization process may involve applying knowledge of the chemical composition of the waste, evaluating the process that generated the waste, gathering information about the waste from available literature including safety data sheets (SDS) and/or profiling the waste material for parameters such as ignitability, corrosivity, reactivity, and/or toxicity.

What can Ranger do for you?

What can Ranger do for you?

Ranger provides a variety of hazardous waste characterization and waste disposal services by using our extensive knowledge and experience to best fit our client’s needs. These services include, but are not limited to:

- Soil, water and chemical characterization

- Hazardous waste containment

- Hazardous waste profiling

- Waste disposal at appropriate facilities